Quick Instruments

Test framework for FPGA board quality control

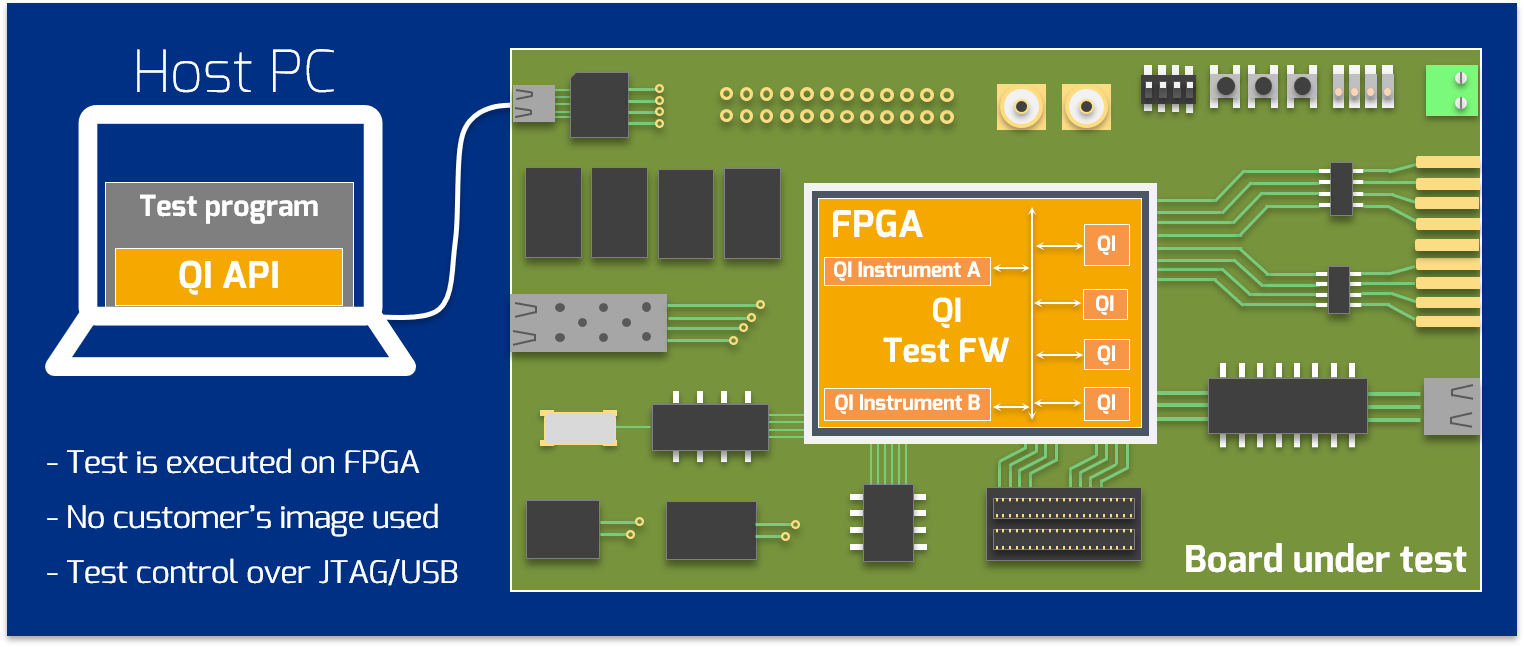

Quick Instruments (QI) is a test & measurement framework that loads itself into on-board FPGA for test, validation or programming purposes. The role of instruments is to verify PCBA hardware infrastructure: on-board interconnections and communication with peripheral components. In this way, every PCBA board can be checked for defects and stability issues. All instruments are pre-compiled for a target board and are being executed from test platform using predefined templates.

QI Toolbox

Transition from crafting to automation

Component | Instrument |

Oscillator | Frequency Counter |

DDR Memory | Memory Tester |

SPI Flash | Flash Programmer |

SERDES links | Bit Error Rate Tester |

Ethernet PHY | Ethernet Tester |

... | ... |

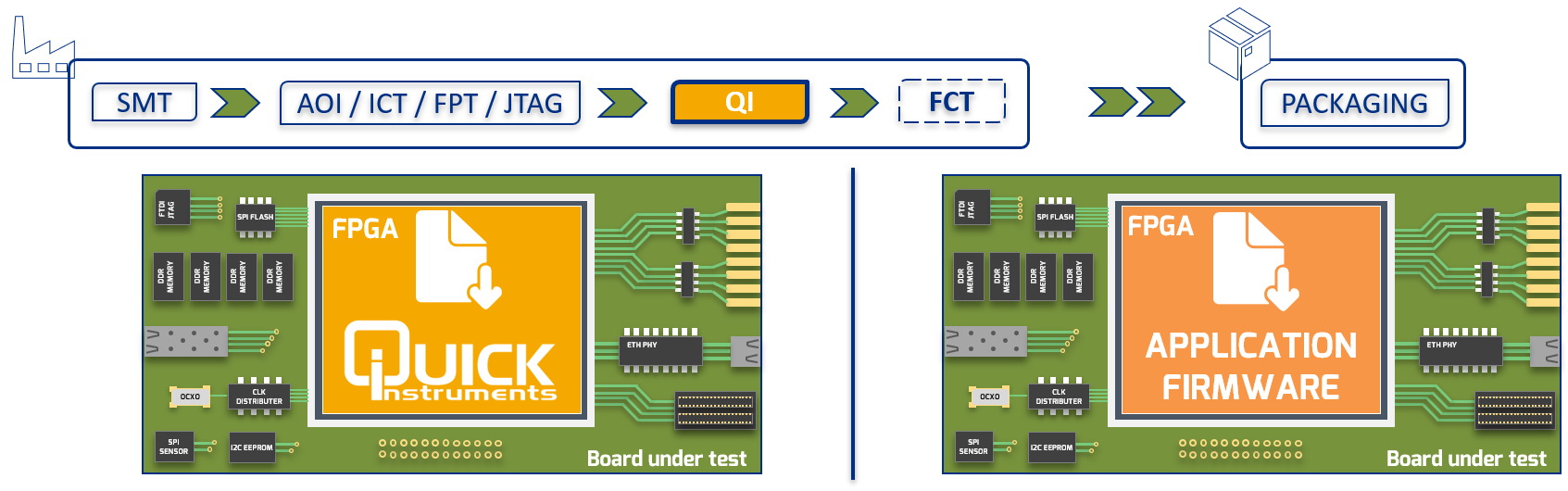

QI test firmware and application firmware synergy

Normally, the QI test firmware loads the user’s application firmware into the board as a last step on a production line.

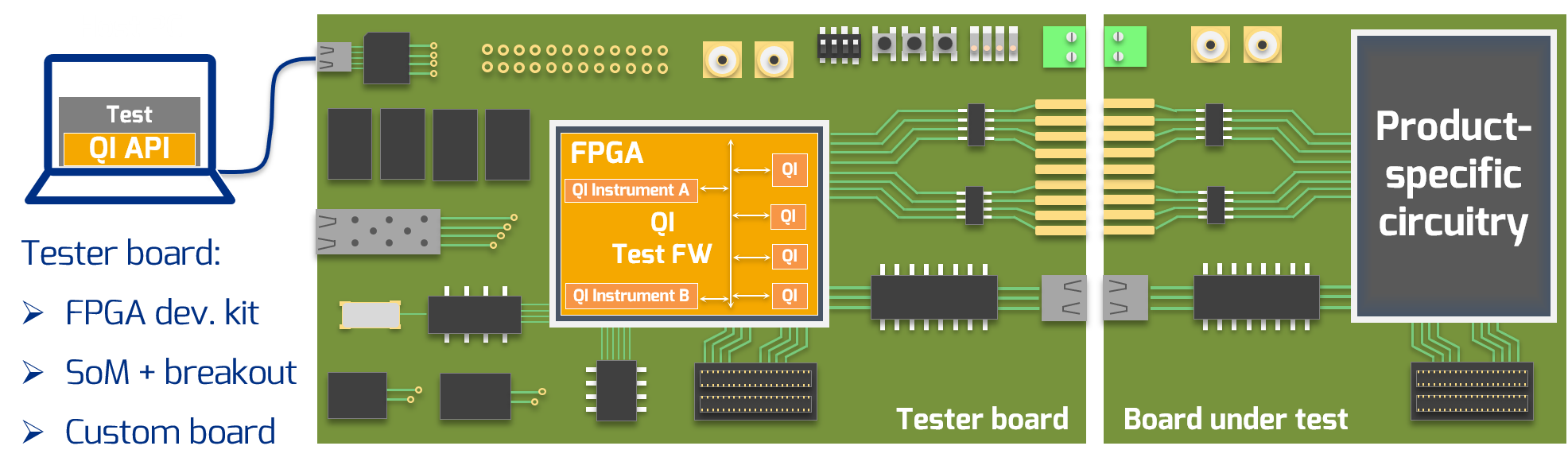

Testing external interfaces

Some target devices are on a board under test and are directly addressable by instrumentation. But some others are just interfaces to the external world. Simple I/O connectors, Ethernet links and high-speed interfaces, like LVDS, SMA, SFP or PCIe are some common examples. A matching board or as simple techniques as looping back some buses or adding some external testers (or matching boards) is the way to get complete coverage.

- Components on a board under test with external connections via I/O or testpoints

- Backplanes, adapters (PCB lines are tested), cables

- Extension board with digital interfaces to DAC/ADCs, PHYs and optical channels

- External flash programming via I/O lines

- Generating static or a clock signal on one side and catching on another

Key Features

Learn more on the Why QI? page

Using Quick Instruments, you can test the board component by component and gigabit links - line by line. In case of a failure, you know exactly which communication bus or line does not work properly. This considerably shortens the searching area and streamlines the repair. The important aspect is that this information is available before the board has left EMS production facilities and product owner does not receive defective PCBAs.