Why Quick Instruments?

We know that testing FPGA boards is a challenging task. We learned all the difficulties that test engineers and board designers are facing and we delivered the framework that addresses all these issues, providing better quality in terms of testing, in terms of a product. Better performance in terms of test execution as well as faster test development for a test engineer. PCBA test is our core competence and we are ready to prove the competitiveness of our solution.

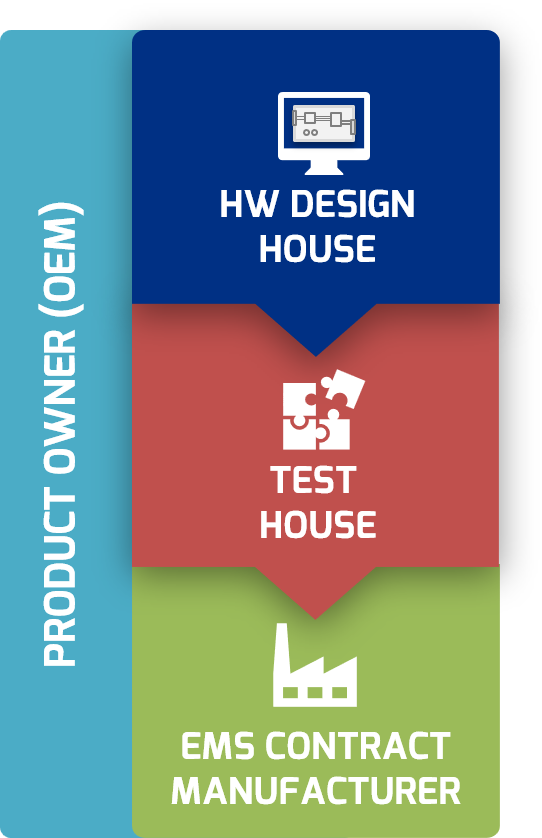

Quick Instruments can be reused from the board design all the way to test development, down to EMS companies and troubleshooting facilities. All of these entities will have clear, certain benefits from using our autogenerated test firmware. Eventually, the product owner (OEM) will be the ultimate beneficiary. His product can be tested on different production stages using firmware which is dedicated by design to test and measurement.

Regardless whether you are a board designer, test engineer or NPI manager working in a OEM, EMS or test solution providing company you will find the benefits of using Quick Instruments for testing FPGA-based products.

Quick Instruments can be reused from the board design all the way to test development, down to EMS companies and troubleshooting facilities. All of these entities will have clear, certain benefits from using our autogenerated test firmware. Eventually, the product owner (OEM) will be the ultimate beneficiary. His product can be tested on different production stages using firmware which is dedicated by design to test and measurement.

Regardless whether you are a board designer, test engineer or NPI manager working in a OEM, EMS or test solution providing company you will find the benefits of using Quick Instruments for testing FPGA-based products.

Catch defects on your board

as early as possible

Defects are an inevitable part of the whole product life cycle. Starting from the product prototype stage, then during the mass production and in the worst case the product is already delivered to the end customer.

Quick Instruments help to detect and localize defects on early stages thus significantly reduce overall development and production costs.

Quick Instruments help to detect and localize defects on early stages thus significantly reduce overall development and production costs.

PCBA test is challenging

Troubleshooting defective boards is generally a complex and time-consuming task. Multiple re-tests, replacement of faulty components and product visual inspections not always give a positive result. Quite often it is hard to debug a problem and many boards remain with an unknown diagnosis.

Quick Instruments are specifically designed to test PCBA components. This helps to separate a problem down to a component

Easy to setup, automate, execute

No need for functional firmware

Quick Instruments can be run on a bare board and provide the tests with known test coverage.

Large ready-to-use QI instrument library

All instruments come off-the-shelf. This allows us to ship the product-specific test firmware in just half a day.

Optimized for short test duration

Quickly validate the quality of produced PCBAs during end-of-line manufacturing tests.

No FPGA design tools / knowledge needed

You get the QI test firmware in the form of compiled FPGA bitstream file.

Quick startup

Predefined API provides a very handy way to work with target devices on the board using Python scripts

Repeatable results

Use the systematic approach that was validated on many other customers’ products around the world.

Customers that already use Quick Instruments for testing PCBAs

Optimize test strategy

The target of application firmware is to fulfill the product specification and make the board works as supposed to.

Quick Instruments check that there are no physical defects on a board.

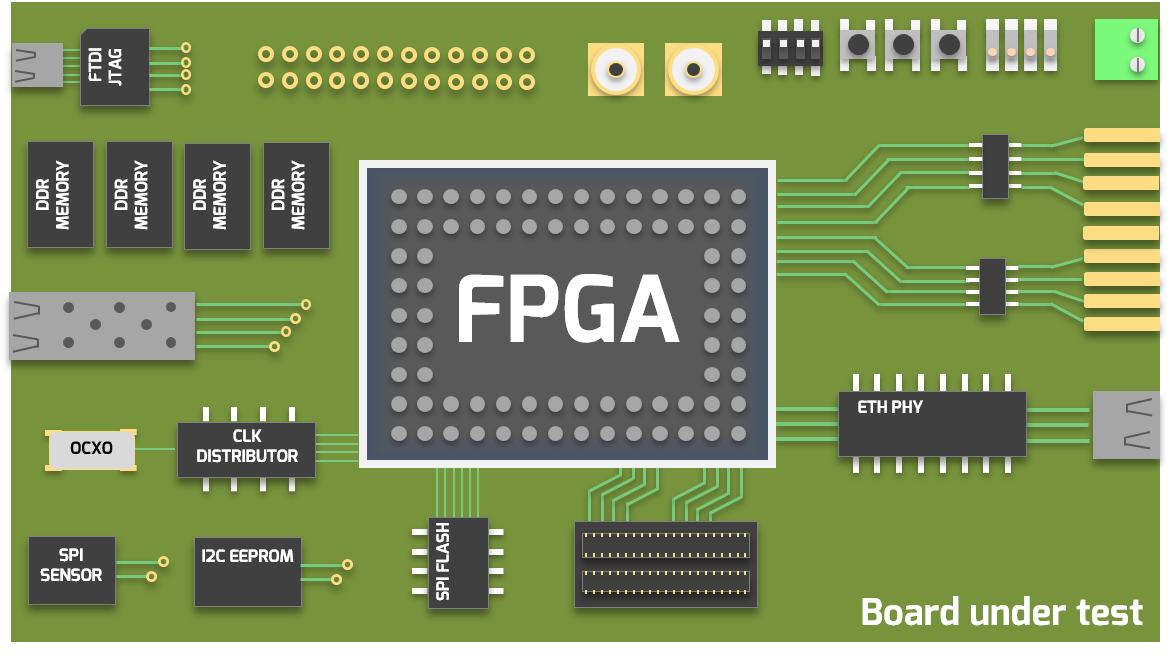

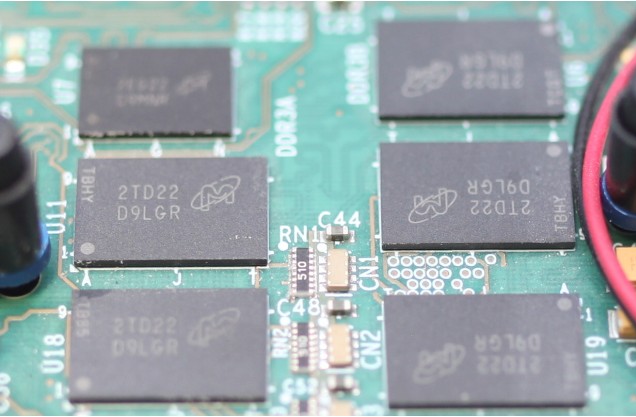

Today, most of the FPGA-based board's functionality has migrated into this large programmable device. The board normally has a standard periphery and high-speed interfaces, like oscillators, DDR memories, SPI flash, I2C / SPI periphery, Ethernet and USB PHYs, I/O connectors. In brief, a set of complex digital components with small footprints, BGA packages, and a limited number of testpoints.

These are key technological trends that also define the ways how we can and should test these boards in the best possible way. Here is the list of standard test methods used in the industry:

These are key technological trends that also define the ways how we can and should test these boards in the best possible way. Here is the list of standard test methods used in the industry:

- In-Circuit Test (ICT)

- Boundary Scan (BS) / JTAG

- Functional test (FCT)

Typical FPGA-based board

Of course, one can apply all of them, but our experience shows that the ability to leverage the functional test to target all the high-speed interfaces, as well as simplify testing of standard peripheral devices and buses, is the key to success.

What we saw before: all functional test strategies were relying on bulky functional testers. The higher speed equipment you have, the better you can test the board. Today this is not enough, because FPGA contains a lot of features, which are concentrated inside and there is no access to them from the outside. Leveraging the processing power of on-board FPGA is the key to success for the contemporary functional test strategy.

No product quality is really possible without the FCT. But then, the functional test has to be implemented in a careful way that addresses the integration trends.

What we saw before: all functional test strategies were relying on bulky functional testers. The higher speed equipment you have, the better you can test the board. Today this is not enough, because FPGA contains a lot of features, which are concentrated inside and there is no access to them from the outside. Leveraging the processing power of on-board FPGA is the key to success for the contemporary functional test strategy.

You actually need to pay more attention to how you program FPGA and how you develop the test program for FPGA so that it can be used during the FCT.

Instruments for everyone

Extend test coverage and speed-up data programming

Frequency Counter

QI Frequency Counter provides a non-invasive way to precisely measure the

frequency of on-board clock signal lines and check whether the frequency is

within the specification range.

frequency of on-board clock signal lines and check whether the frequency is

within the specification range.

There is no need to use test probes, external equipment, and fixture cables as all measurements are done inside a product under test.

In-System Flash Programmer

QI Flash Programmer delivers superior performance and does not require test points. It is more tolerant to signal integrity issues (compared to external ISP programmers) and due to its nature can be replicated for free.

No hardware, same high-speed programming (3Mbps).

Memory Interconnect Tester

With QI Memory Tester, you can detect the memory bus issues before you a running any software on the board. The memory tester applies specifically selected test patterns in order to catch both gross (opens and shorts) and marginal defects.

The test is done on the operational speed of the memory bus in conformance with all timing characteristics.

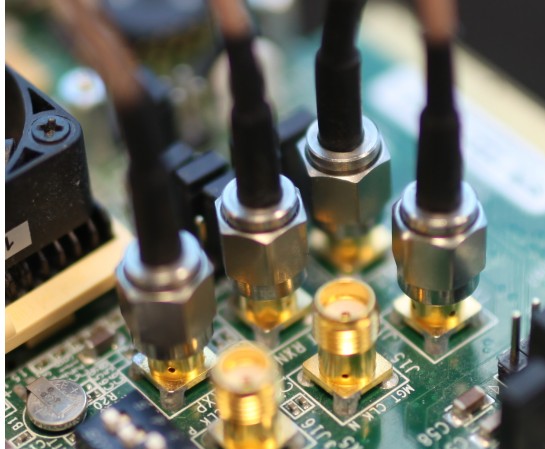

Bit Error Rate Tester (BERT)

QI BER Tester gives the possibility to test the gigabit links on a physical layer during end-of-line tests. The measurement takes only several seconds and fits the production in-line test.

QI Eye BER Tester is also able to visualize the results with a BER Eye diagram.

QI Eye BER Tester is also able to visualize the results with a BER Eye diagram.

Unlike to traditional approach when only a couple of boards from a batch is tested using expensive external T&M equipment, using QI BER Tester you can test every product for manufacturing defects.

Cost saving

Off-the-shelf products are cheaper than manual development

Hand-coding a test solution for an FPGA-based board requires a lot of time and effort. Test engineers usually have very little understanding of FPGA design. FPGA developers are a limited workforce and their primary task is to close all functional requirements that the product and firmware need to fulfill.

The core idea of the Quick Instruments framework is that although every FPGA-based product has its own functionality, every PCBA is very similar from the hardware point of view. It contains a lot of typical components, like oscillators, SPI flashes, DDR memories, Ethernet PHYs, high-speed links, etc. The test of these ICs and communication buses can be standardized and fully automated.

All our instruments are pre-developed, fetched from the off-the-shelf instrumentation library and compiled for a particular board under test using our back-end compilation servers. As a result, ready-to-use test firmware is available in just half a day!

The core idea of the Quick Instruments framework is that although every FPGA-based product has its own functionality, every PCBA is very similar from the hardware point of view. It contains a lot of typical components, like oscillators, SPI flashes, DDR memories, Ethernet PHYs, high-speed links, etc. The test of these ICs and communication buses can be standardized and fully automated.

There is no need to develop manually a test firmware for each of the products.

All our instruments are pre-developed, fetched from the off-the-shelf instrumentation library and compiled for a particular board under test using our back-end compilation servers. As a result, ready-to-use test firmware is available in just half a day!

Critical challenges when the application firmware is reused

What we see on the market, is that the typical test solution for an FPGA-based product is a modification of an application firmware for test purposes. However, quite often this approach is not efficient as it is time consuming, it has limited test coverage and it is difficult to integrate and automate the final solution into the end-of-line manufacturing test workflow.

There are certain drawbacks of using the application firmware for test:

There are certain drawbacks of using the application firmware for test:

- The firmware may not be ready when it is needed, e.g. when the test is being developed.

- It is difficult to integrate the firmware into a test setup on a production line

- Quite often, no diagnostic information in case of a fail

- It may be incomplete or some necessary operations modes are missing.

- Documentation for the firmware may still be missing when it is needed.

Using Quick Instruments, you test the board component by component and gigabit links - line by line. All tests are optimized for short test duration and can be executed at any product lifecycle stage. The instruments are working in the same conditions which a board designer planned and in the same way as the FPGA designer will run the application. In case of a failure, you know exactly which communication bus or line does not work properly. This considerably shortens the searching area and streamlines the repair. The important aspect is that this information is available before the board has left production facilities.

Get Started with Quick Instruments

Schedule a demo

Book a personalized demo to learn how Quick Instruments can help to test your FPGA-based product.

Request a demoGet a quote for your project

Provide us with information about your project and we will provide you with a personalized quote.

Request a quoteHave a question?

Everyone has specific requirements. Tell us about them and we will try to provide a solution!

Contact us